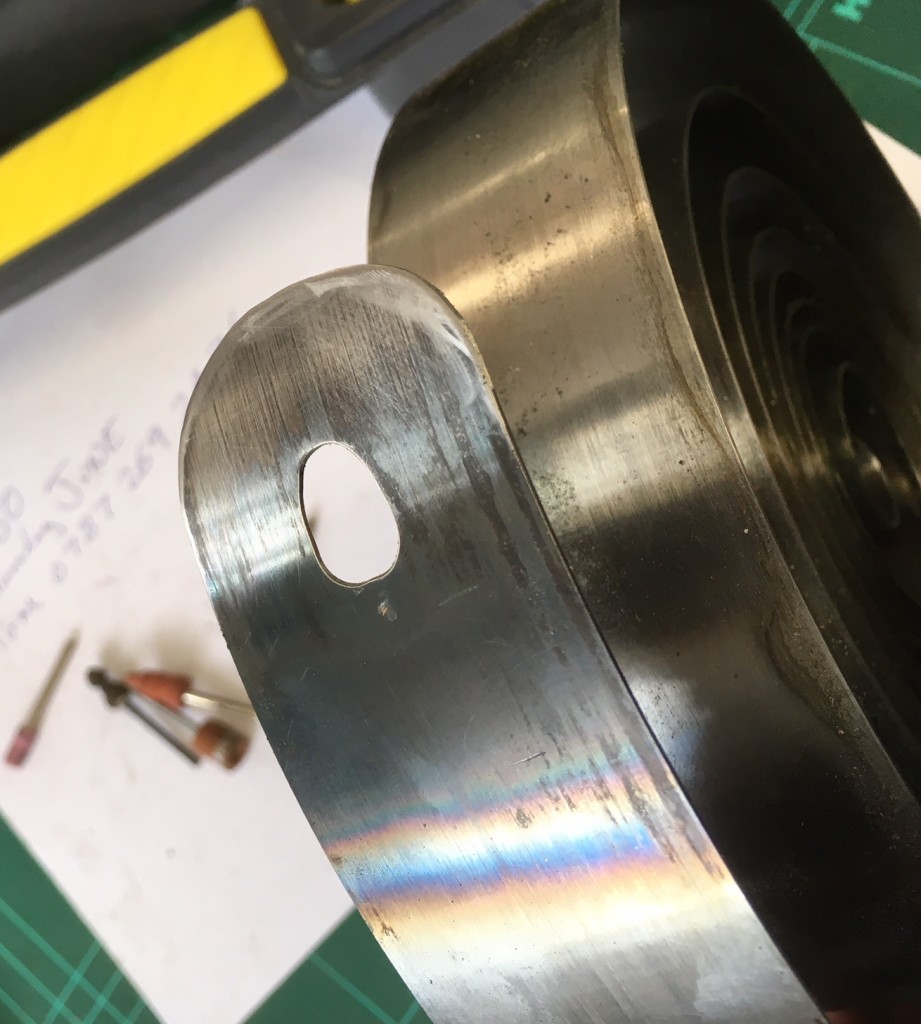

On a large automaton of Little Tich, the 19th century music hall performer. The large mainspring was found to have its hole torn out from the barrel hooking. This is a fairly common repair, a result of ‘overwinding’.

The secret to the repair is the process of softening the steel prior to punching and shaping a new hole.

The new end will be curved to fit the shape of the barrel and then the spring cleaned and greased before fitting.